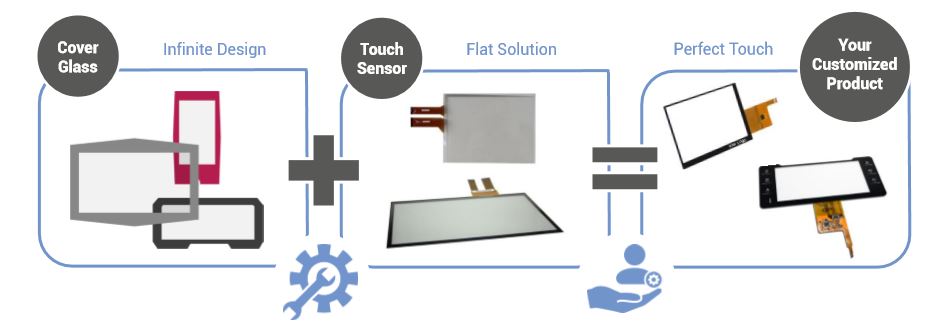

Our Customised Touch Design

Many versions of PCAP Touch Screens from 1.77" to 75"

Options of projected capacitive touch screen and a design to suit your requirements.

Modular touch solutions to give you the perfect design

Infinite Touch Design Guide

Infinite Touch Features

- Special glass shapes

- Coloured prints in your favorite colours

- Logo prints Special coatings, such as anti-glare or privacy filter

- Shatterproof cover glasses in different strengths for public areas

- Chemically strengthened glass

- Aluminosilicate glass (Dragon, Gorilla, Panda, Xensation)

Glass processing

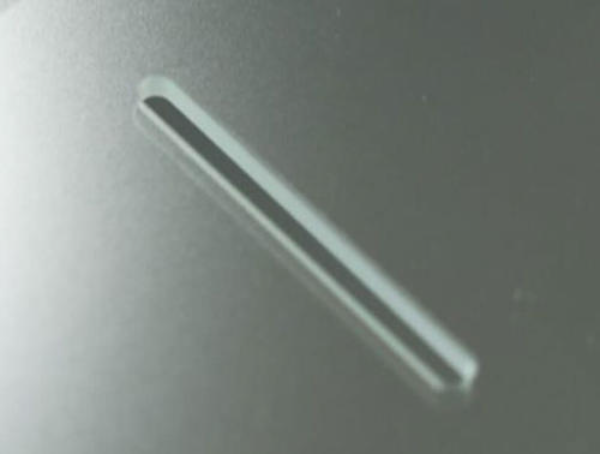

- Cutouts, holes

- Fingertip recess or slider (circular / elongated), polished or ground

- Edges, steps or grooves

Infinite Touch Features

Edge to Edge 'TrueFlat Glass' Projected Capacitive (PCAP) Technology

Cover Glass: Bespoke user-defined shape, machine-finished edges & application specific cut-outs

Rear ceramic screen printing for corporate branding, product names and user interface icons

Glass Options: Low ion, Anti-reflective (AR), Anti-glare (AG), chemically toughened, Gorilla glass

Multi-touch: Up to 10-points with USB and I²C interface

Ideal for strip or optical bonding

We can support prototypes with no minimum order quantity (MOQ) and cost effective tooling

Sizes: Up to 32" available

The Design Process

As a bespoke solution you have the design freedom to create a touch screen to fit your exacting requirements. Using VacuBond technology we can optically bond the touch screen to your chosen TFT display unit.

Step1: Define your cover glass

Design your individual cover glass from a whole host of options.

Size: custom

Design: infinite

Floatglass: chemically or thermically toughened

Surface: AG (anti-glare) or AR (anti-reflection)

Print: organic, digital, ceramic (therm. tough. only) opaque/lightproof, single/multi-colour for customer logo, buttons, passe-partout

Edges: ground, faceted, c-cut, polished

Other glass: laminated safety glass, Xensation, etc.

Special: antibacterial glass

Step 2: Choose your touch foils & sensors

Using touch foils instead of a conventional touch screen eliminates a glass layer between TFT display and cover glass. This saves space and delivers better optical results.

Check out our touch sensor and foils guide for more detailed information.

Step 3: Deliver a customised product to suit your application

The touch sensors will then be optically bonded using VacuBond to the rear glass to deliver your finished product.

Your requirements determine the final product

We use our autoclave to laminate touch films in sizes ranging from 1.77" to 32" on customized cover glasses. By using a touch foil instead of a conventional touch screen we eliminate a glass layer between TFT display and cover glass.

This saves space and gives better optical results.

With our VacuBond technology we can optically bond the touch screens with a display of your choice from our TFT program to one unit.

In addition to the customized designs, we offer the PCAP touch screens as a standard product with black or white sealing.

Antiviral protection film/ Antibacterial glass

Our robust antibacterial and antiviral display protection film releases copper ions that destroy viruses - including SARS-CoV-2 - and bacteria within minutes and significantly reduces the risk of infection from touch surfaces. Nevertheless, the film is crystal clear and tolerates all common cleaning agents. For our POS-PRO monitors and for projects, we apply the film precisely to our display solutions.

Antibacterial glass contains silver ions that reliably kill bacteria such as Escherichia coli or Staphylococcus aureus. They are also optionally available with AR or Easy-to-Clean coating and are particularly suitable for areas with high hygienic requirements, for example in the medical field.

Special coatings and filters

Different coatings and filters on the glasses or lenses bring advantages for special areas of application:

- Antiglare and antireflection filters improve the readability of the display in sunlight and reduce reflections

- Privacy filters prevent viewing of screen contents when viewed from the side and protect the privacy of the user

- Easy-to-clean and anti-smut (AS) coatings offer a lotus effect and make cleaning the glass surfaces easier

- IR filters prevent the heating of the display by the front infrared radiation of the sun

- UV filters prevent the harmful long-term effects of the aggressive UV radiation from the sunlight

Splinter protection according to DIN EN12600

Should a protective glass break due to impact or force, sharp-edged splinters may result, posing a risk of injury. Especially in public areas or in food production, this creates a considerable risk potential that can be avoided by applying a splinter protection film. The glass will break, but there will be no dangerous splinters.

The film is cut to fit the protective glass, it comes laminated and includes the following benefits:

- scratch resistance of 3H

- consist of a PET / PVC material

- are only approx. 120 µm thin

- can be cleaned with alcohol-based cleaners

- comply with EN 12600 2B2 standard and are REACH and RoHS compliant

Your requirements determine the final product.

We use our autoclave to laminate touch films in sizes ranging from 1.77" to 32" on customized cover glasses. By using a touch foil instead of a conventional touch screen we eliminate a glass layer between TFT display and cover glass.

This saves space and gives better optical results.

With our VacuBond technology we can optically bond the touch screens with a display of your choice from our TFT program to one unit.

In addition to the customised designs, we offer the PCAP touch screens as a standard product with black or white sealing.